Description

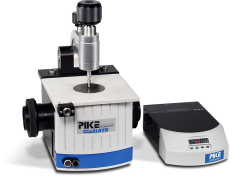

The PIKE ReactorMAX is a fully automated, variable angle ATR accessory equipped with a temperature-controlled pressure vessel. The design employs a unique optical layout of the ATRMax (U.S. patent 5,105,196), which enables samples to be analyzed over a range of incident angles.

Variable angle of incidence provides experimental control over the depth of penetration of the IR beam into the sample and the number of beam reflections in the ATR crystal. Integrated reaction vessel may be pressurized up to 55 bar and heated to 215 C. Optional stirring is available.

- Selectable angle of incidence from 25 to 65 degrees

- 0.5 to 10 micron depth of penetration – dependent on crystal material, angle of incidence, sample’s refractive index and wavelength of IR beam – ideal for depth profiling studies

- 3 to 12 reflections of IR beam – dependent upon angle of incidence – ideal for optimizing ATR sampling methods

- Variable temperature control to 215 °C

- Sealed sample chamber for pressures to 55 bar

- Optional in chamber stirrer (shown above)

- Automated incidence angle control and TempPRO™ software for high-precision experiments

The ReactorMAX is equipped with a temperature-controlled pressure vessel that may be heated up to 215 °C and operated up to 55 bar. Optional stirring is available. The material of the pressure vessel is Hastelloy, capable of withstanding extremely harsh chemicals under pressure/temperature conditions. Integrated into the bottom of the vessel is a multiple reflection AMTIR ATR crystal.

With a pH tolerance between 1-9, AMTIR offers a robust ATR crystal for a wide range of applications. ReactorMAX ATR element is a trapezoidal shape and 56-mm long, 10-mm wide and 4-mm thick. Standard bevel angles at each end of the AMTIR crystal are available in 45- and 60-degree versions.

Coupling the variable angle of incidence of the ReactorMAX with the variable crystal face angles, one can select effective angle of incidence ranging from 35 to 65 degrees and the range in number of reflections from 3 to 9. Contact PIKE for other ATR crystal material options.

The control of angle selection, temperature and stirring speed is automated and integrated into PIKE software. Automation streamlines experimental protocols; the entire experiment can be programmed and executed by the computer.

Advantages of the automated features include:

- Computer controlled precision, accuracy and repeatability

- Synchronization of mirror position changes with collection of sample spectra

- Full integration of the PIKE Technologies software with most FTIR spectrometer programs for data collection

- Tailor-made, predefined experiments

- “Hands-free” operation

Datasheet