Description

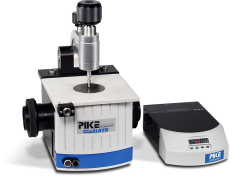

Specac Golden Gate Diamond ATR

Outstanding sensitivity is achieved using high pressure contact against a solid, type IIIa diamond, selected for its unparalleled sensitivity as a single reflection ATR element together with its unique physical and chemical stability.

The accessory can be used to analyze a range of samples from single particles and fibers to corrosive liquids. While the large working area sample platform is ideal for macro sampling.

The diamond is high temperature bonded into its tungsten carbide mount, giving performance and strength to withstand the high pressures required for maximum optical contact with hard samples.

The quick lock and release bridge allows for fast sample change around. The built-in pressure control mechanism means reproducible results are obtainable and optimum sample clamping is achieved.

Polarization studies can be carried out using the Benchmark® polarizer mount.

Ultimate sensitivity and reproducibility

A key feature of the Golden Gate® Single Reflection ATR System is the outstanding contact achievable between solid samples and the diamond crystal. For many sample types (particularly powders and fibers), as the load is applied to the sample and optical contact between the diamond and the sample increases, the intensity of the absorbance bands also increase. In other words, increasing the load increases the sensitivity. The Golden Gate® gives the highest load capability of any commercial diamond ATR (over 180 lbs) and the diagrams above illustrate how that impacts sensitivity for a variety of sample types. For softer samples, such as polymers, a similar effect is seen. However, once the sample has fully contacted the ATR surface, the absorbance stops increasing with increasing pressure. In order to achieve the best measurement repeatability and reproducibility for these samples, the instrument should ideally apply a load above the “knee” of the curve where the absorbance becomes much less sensitive to load. The diagrams above illustrate some measurements for typical samples. Note how the harder sample types need a higher load to reach this ideal situation – and very often the Golden Gate® is the only product that can do it.

Key Features

- High sample throughput – no preparation

- Rugged type IIIa diamond ATR metal-bonded into a tungsten carbide mount

- Hard, inert, sapphire self-levelling pressure anvil

- Pressure bridge for highest sensitivity

- A wide choice of available options

- Quick release bridge with safety interlock

- Built-in pressure control for reproducible results

Applications

- QA on pharmaceutical powders

- Analysis of hard and soft polymer pellets

- Forensic sampling, paint chips and single fibers

- Hard samples, e.g. rock and geochemicals

- Corrosive liquids

- Coated wires

- Air sensitive samples

Download Application Notes:

Narcotic Analysis Heated Soil Analysis Powdered Solid Analysis Automotive Polymers Analysis Automotive Fluid Analysis African Crested Rat Analysis