Photochemical ATR measurements

Photocuring, or the solidification of a liquid mixture (e.g. resin) upon exposure to light, is a widely adopted method for dental coatings and sealants, medical adhesives, photoresists, and 3D printing. Tracking this process in real-time enables resin optimization, tailored for a particular application. Fourier-transform infrared spectroscopy-attenuated total reflectance (FTIR-ATR) is a facile way to monitor the solidification process through changes in chemical functionality and determine reaction kinetics and efficiency at the ATR crystal interface.

Conventional photochemical ATR setups irradiate samples from top-down, while IR measurements are taken from the bottom-up. This disparity results in a difference in light intensity throughout the depth of the sample due to absorption and sample thickness non-uniformity, which limits the accuracy of analysis, and mitigates characterization of opaque resins.

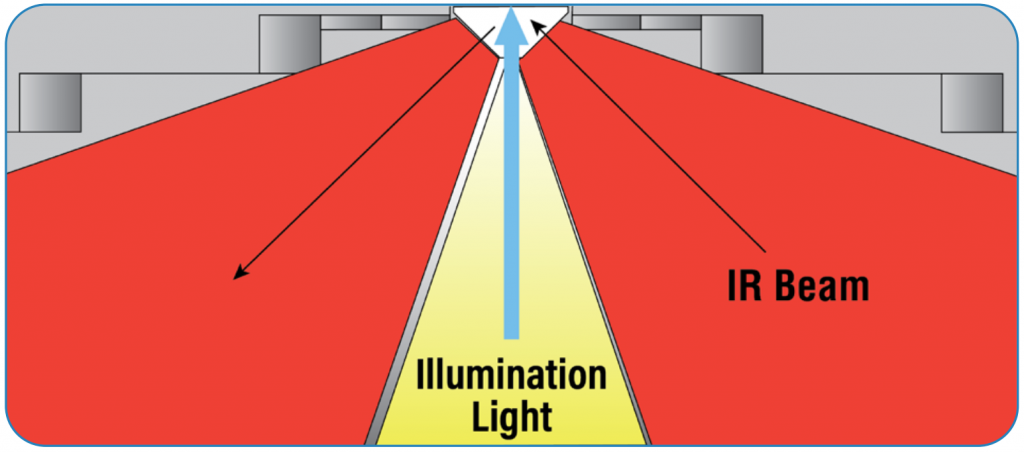

The new Pike GladiATR Illuminate overcomes these challenges using illumination from beneath the sample through a diamond ATR prism, aligning the absorption cross section of the sample with the evanescent wave of the IR beam for characterization.

The GladiATR diamond ATR was modified to incorporate a liquid light guide that enables illumination from beneath the diamond. The liquid light guide imparts modularity, as numerous light sources with variable wavelengths and intensities can be directly coupled for photocuring purposes.

The GladiATR Illuminate optical design is all reflective, preserving the full spectral range inherent to diamond. For standard mid-IR FTIR spectrometers, the spectral range available with the GladiATR Illuminate will be 4000–400 cm-1. For FTIR spectrometers equipped with far-IR optics, the spectral range is extended to less than 50 cm-1.

Temperature controlled crystal plates are available for thermal study of materials. The resistively heated diamond plate has a temperature range from ambient to 210 oC. PIKE Technologies offers temperature controllers with digital and PC programmable set points with TempPRO software (sold separately). This allows for easily programmed temperature profiles and unattended data collection with most FTIR software platforms. For applications requiring temperatures from sub-ambient to 210 oC, liquid jacketed plates are available.

The GladiATR Illuminate diamond ATR is available in configurations to fit most FTIR spectrometers.

Photopolymerization of an acrylate based resin

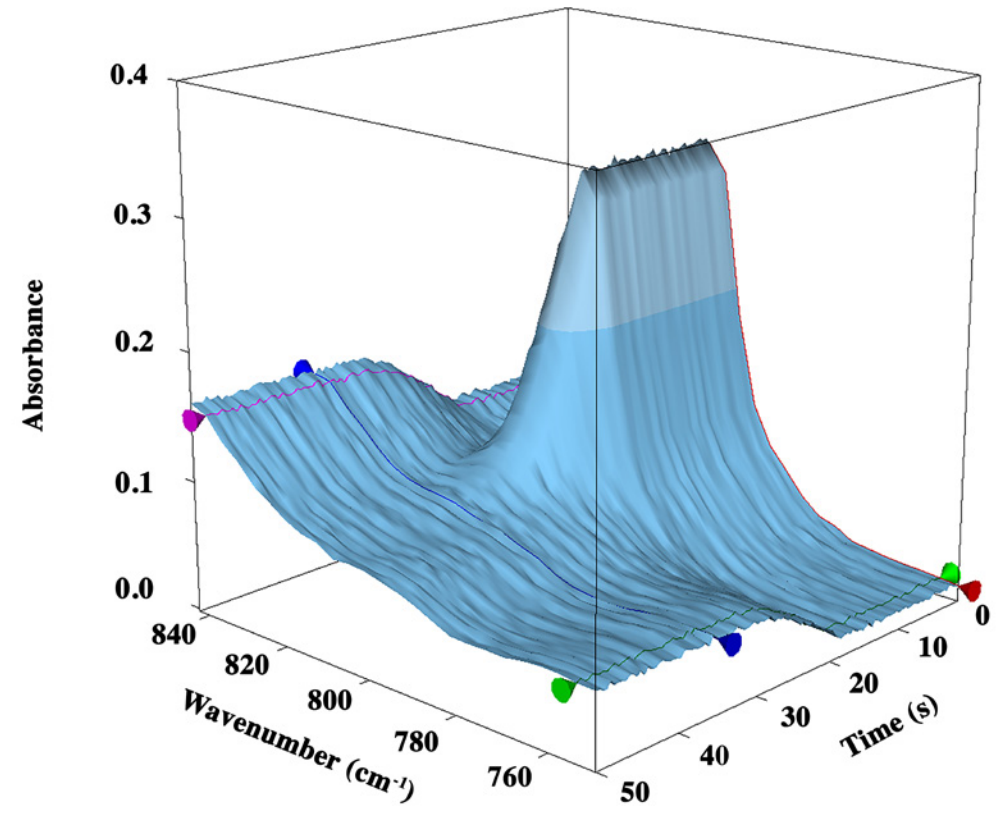

To demonstrate the capabilities of the light guide coupled GladiATR, photopolymerization of an acrylate- based resin using violet light (λmax = 405 nm) was performed. The resin comprised carbitol acrylate and diphenyl (2,4,6-trimethylbenzoyl) phosphine oxide (TPO, 1 wt%). Approximately 20 μl of resin were placed on the ATR crystal and real-time tracking was initiated. After 19 second, the sample was irradiated with 405 nm light at an intensity of 36 mW/cm2. The FTIR instrument scan rate was 80 kHz while using an MCT detector, and 4 scan were co-added.

Polymerization results

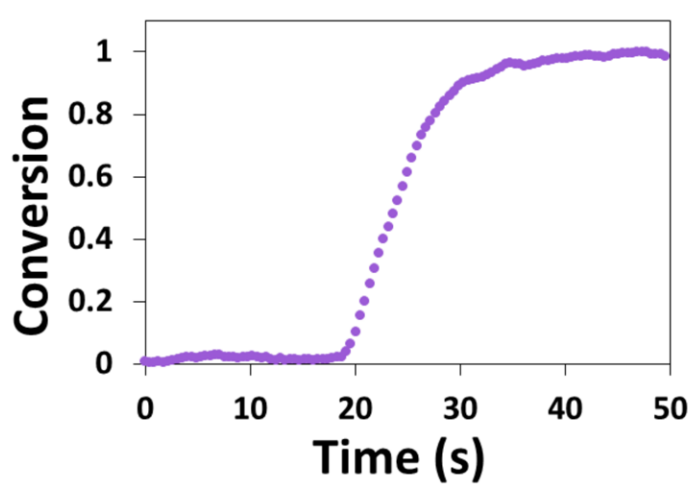

The polymerization was monitored by observing the disappearance of the C=C-H wag band at 810 cm-1 (Figure 2). Within 20 seconds of irradiation, the conversion was approximately 98% as shown in Figure 3. A clear initiation was observed at time of irradiation, indicating no lag time between the light and measurement.

Conclusion

Monitoring UV curing via FTIR-ATR by illuminating the sample from underneath offers a quantifiable sampling method to determine reaction kinetics. The modular capabilities of the ATR accessory allow for curing using any UV-visible wavelength.