Description

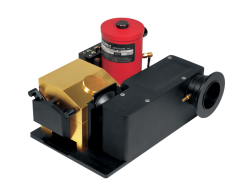

Specac Specular Reflectance Accessory 30°

Specular reflectance is a non-destructive method for surface measurements using a mirror-like reflection from the shiny or semi-matt surface of a sample. Specular reflectance occurs when the reflected angle of infrared radiation equals the angle of incidence. The amount of light reflected depends on the angle of incidence, the refractive index, surface roughness and absorption properties of the sample.

The fixed angle specular reflectance accessory allows for a beam of radiation at a fixed angle of 30 degrees incidence to fall upon the surface of a solid material, in order to gain spectroscopic information on any surface layers of the flat solid sample. (Liquids or gums etc. cannot be analyzed due to the orientation of the sample).

The solid sample is inverted and placed over the aperture at the top of the accessory. The incident beam is projected from a fixed mirror block surface to the sample surface and is specularly reflected from the sample surface back to the fixed mirror block and then directed to the detector. The sample spectral collection is carried out after a reference spectrum has been collected using the reference mirror (supplied) in place of the sample. There are two different aperture stops (5mm and 10mm dia.) that can be used to mask down the area of study on the sample if desired. The sample sits flat over the aperture and its size is necessarily limited by the dimensions of the sample compartment and the size of the aperture stop chosen.

The accessory is installed within a spectrometer using a Benchmark® type baseplate and so when ordering, you need to state which spectrometer is to be used to receive the appropriate baseplate.

Key features

- 30º fixed angle

- Convenient horizontal sample position (20.8mm diameter full aperture)

- Accommodates powder samples

- Suitable for dispersive and large beam FT-IR

- Minimal alignment

Applications

- Analysis of surface coatings (polymer, optical)

- Local analysis of defects and inclusions

- Fragile samples